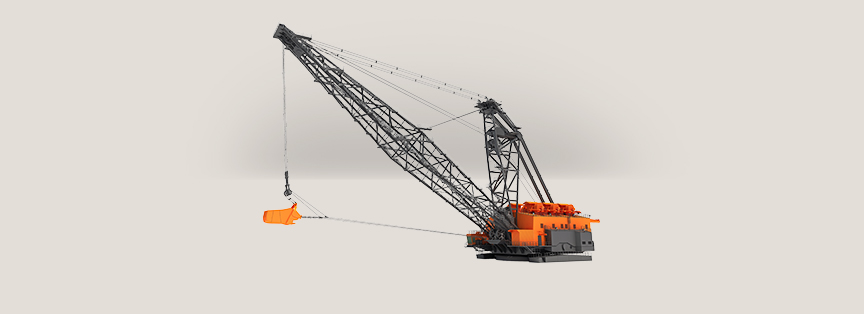

Shovels

Digging deeper

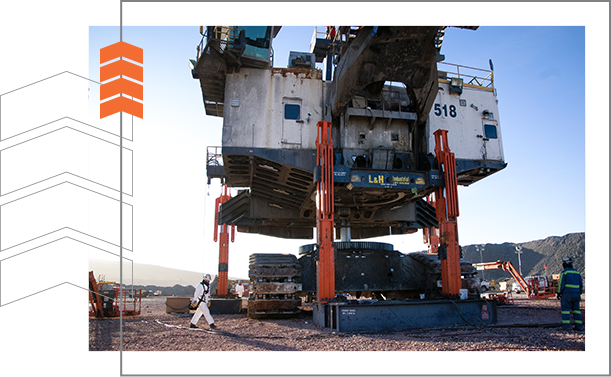

Shovel down again? L&H Industrial overhauls mining shovels across the globe, finding solutions to problems others won’t even touch. With mechanical expertise gained over 60 years working alongside the very best in the mining industry, our modifications drastically reduce maintenance downtime for shovels, and components that consistently last 30% longer than OEM systems.

Improving Operations

If it’s broken, we can fix it. Every day we transform complete shovel systems to dramatically improve performance and safety while minimizing downtime and cost of ownership. With expert engineering and precision manufacturing, we extend component, assembly, and equipment life and back that up with 24/7 responsive field services.

Rebuilding Better

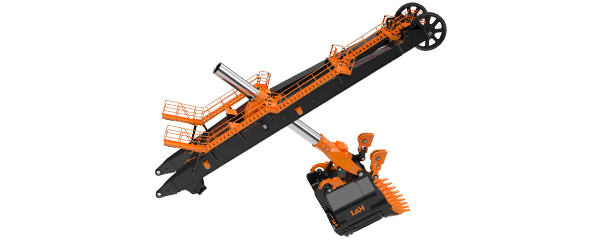

L&H specialists are ready to design, engineer, manufacture, and monitor upgraded components and assemblies for mining equipment, electric rope shovels, and hydraulic excavators. We’ll rebuild and improve any major systems and structures, including the hoist, swing, crowd, and propel systems; as well as structures and attachments including booms, side frames, handles, and dippers. If you require a custom solution, we’ll design, build, and install on-site, so you can get back to production and achieve your operational goals.

L&H Innovations

Our nimble and practical partnership approach paired with our superior design, engineering, manufacturing, monitoring, and field service capabilities offers solutions that transform shovel operating efficiencies including our industry leading undercarriage designs.

Direct REplacements

We bring our huge industry experience to all major sections of your shovel and excavator fleet. From the dipper or clam to the undercarriage system that carries it all—the shoes, L&H offers direct replacements for all parts of the machine. We can also build them better.

Custom Solutions

No job is too big for our expert teams—from major outages to component overhauls, custom tooling, and fixtures, or a unique custom need for your shovel fleet.

Simply

unmatched

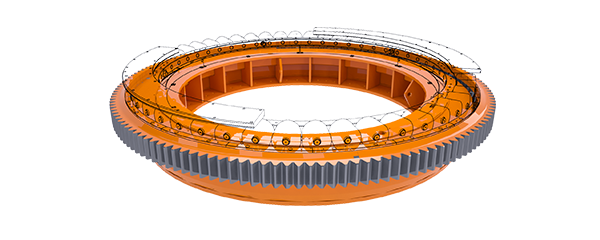

Undercarriages

L&H undercarriages include side frames with thicker inner plates to reduce structural wear and last 30% longer than OEM undercarriages.

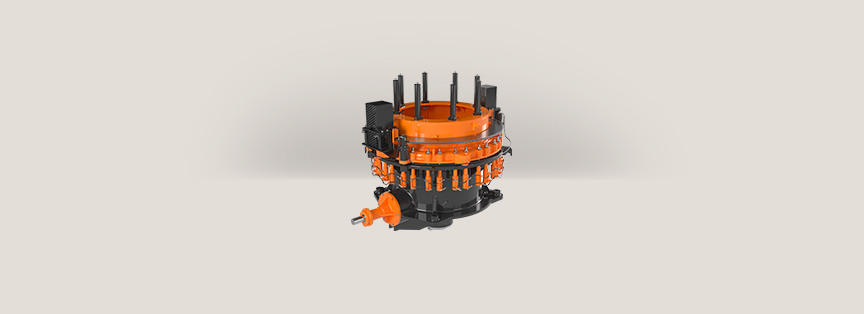

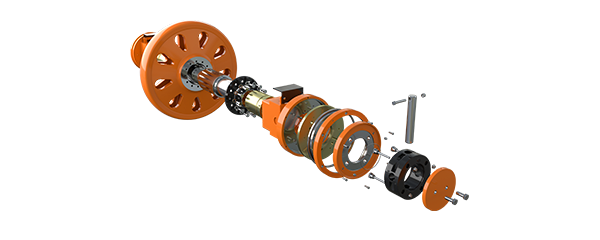

Swing Systems

L&H Swing Systems have universal bolt patterns and 300% more thrust surface.

Front End Attachments

Shifting from castings to high-quality forgings, optimizing weld seams, and refining manufacturing processes, we ensure superior reliability across all front end components over original designs.

Components

100% of L&H premium components meet, or more often exceed, OEM performance, quality, and safety standards.

House Machinery

L&H has deep experience improving house machinery with builds, rebuilds, and exchanges of crowd transmissions, plus structural improvements to transmissions, and gearing enhancements with machining up to AGMA 12.

Custom Tooling

L&H design and engineering teams routinely tailor tools including final drive strong back and shaft handling tools and swing pinion installation tools that improve safety and efficiency for shovel maintenance teams working in the field.

READY TO INCREASE

PRODUCTIVITY?

Components & Assemblies We Enhance

Rope Shovels

undercarriage

• Track Shoes

• Front Idlers

• Load and Idler Rollers

• Final Drive Assemblies

• Track Slides

• Sideframes

• Carbodies

• Final Drive Transmissions

• Lubrication Systems

swing system

• Swing Pedestals

• Swing Racking and Rails

• Roller Ciricle Systems

• Swing Transmissions

• Swing Girders

• Center Pins and Bushings

• Swing Shafts and Pinions

• Lubrication Systems

crowd system

• Dipper Handles / Sticks

• Crowd Racking

• Crowd Transmissions and Gearing

• Hydracrowd® Components

• Crowd Drum (Rope Crowds)

• Shipper Shafts

• Saddle Blocks

• Rope Sheaves

• Lubrication Systems

hoist system

• Hoist Transmissions

• Hoist Drums

• Hoist Pedestals, Mounting Pins and Bushings

• Bull Gearing

• Hoist Pinion Assemblies

• Lubrication Systems

attachments & structures

• Boom

• Boom Point Sheaves

• Gantry / A-Frame

• Green Horn

• Boom Bumpers

• Handrails / Catwalks

• Lubrication Systems

• Dippers

• Padlocks

• Equalizers

• Pins and Bushings

• Lubrication Systems

Hydraulic Excavators

undercarriage

• Track Shoes

• Front Idlers

• Bottom and Top Rollers

• Final Drive Assemblies

• Sprockets

• Track Slides

• Final Drive Transmissions

• Lubrication Systems

hydraulic systems

• Hydraulic Cylinders (New and Rebuild)

• Hydraulic Pumps and Motors

attachments

• Booms

• Sticks

• Clams / Buckets

• Backwalls

• Pins and Bushings

swing systems

• Slewing Rings

• Swing Transmissions

• Swing Motors

Brands We Make Even Better

Field Services We Offer

· Field welding and machining services

· Full/partial machine rebuilds/outages

· Rush breakdown repairs

· NDT services and analysis

· Failure analysis and troubleshooting

· Full machine audits and inspections

· Equipment relocations

· Machine customizations

· Custom tooling design

Technical Data Sheets

Case Studies

Have A Big

Challenge?

We’re ready for anything.

No problem is too big or too small. Our expert engineers, manufacturers, and field service technicians love a good challenge and routinely solve complex issues for operations globally.