railroad

railway

Revolution

With 60 years of expert engineering experience and custom heavy-equipment manufacturing capabilities, L&H Industrial improves railroad maintenance-of-way equipment for operations around the world. We’ve honed our world-renowned edge by working side-by-side with our railroad partners to improve quality and safety while radically reducing downtime for optimal production.

Mechanical Expertise

Our railroad equipment rebuilds, repairs, modifications, and innovative designs showcase the spectrum of our machine engineering and custom manufacturing capabilities. L&H provides MOW equipment solutions including superior assemblies and one-of-a-kind custom solutions for class 1 railroads. Our advanced technologies allow for safer operation with higher performance and lower downtime and maintenance. And we back it all with 24/7 responsive service and technical experts in your corner to solve your biggest challenges.

L&H Innovations

Our specialized designers and engineers are proud to collaborate with industry leaders to develop advanced technologies for railroad maintenance of way equipment that improve safety and performance. We worked with BNSF Railway to design, engineer, prototype, test, and manufacture a simpler, more precise, and safer-to-use automatic pregauger machine that aligns plates for threading new rail.

Direct Replacements

With extensive industry experience we’ve developed a comprehensive offering of MOW equipment parts and assemblies including cylinders, axles, and more. Our world-class replacement components improve safety while reducing downtime and are in stock and ready for you when you need them.

Custom Solutions

We’re ready to step in and create custom solutions for railway equipment using superior metallurgy, designs, and customer feedback. Our Tie Crane Boom eliminates chronic OEM design issues and premature failures and with radically improved performance, safety, and increased life through our custom design and manufacturing of Regulator Wings and Bucketwheel Excavators. No challenge is too big for our specialized team.

Leave Downtime

In The Dust

Design & Engineering

Optimize your operations with the expertise our team brings to developing one-of-a-kind innovations and advanced technology for heavy equipment across industries.

Manufacturing & Repair

Our world-class team of specialists manufactures and repairs components and assemblies using precision equipment in state-of-the-art facilities to improve operational safety and performance.

Monitoring & Controls

Our comprehensive digital solutions provide real-time insights for predictive maintenance and machine monitoring, ensuring you have the data you need, whenever you need it.

Field Services

Our experienced crew collaborates with and works alongside your team to troubleshoot, repair, rebuild, install, and even relocate your heavy equipment.

Simply

unmatched

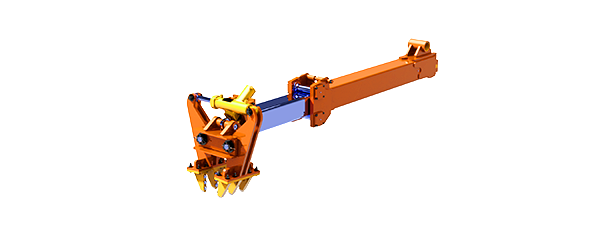

Tie Crane Boom

Premium L&H design and manufacturing reduces cracking for a critical component that lasts at least 30% longer.

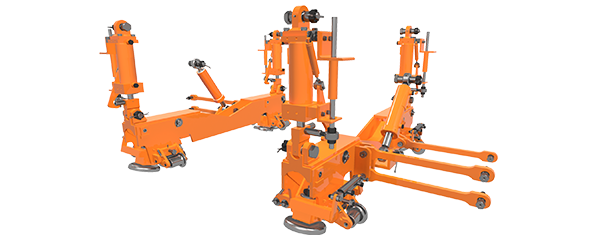

Regulator Wings

Manufactured to eliminate cracking in high-stress areas by over 50% through custom design and material improvements.

Components

100% of L&H premium components meet, or more often exceed, OEM performance, quality, and safety standards.

Tie Knockout Lift Table

Custom designed and manufactured for production tie exchangers to be low-wear, 35% stronger than similar products, and outlast OEM assemblies 5:1.

Ready to extend the life of your MOW equipment?

Components & Assemblies We Enhance

Railroad equipment:

· MOW equipment

· Ballast regulators

· Tie cranes

· Bridge cranes

· Spiker puller

· Spiker driver

· Tamping machines

· Pregauger

· Bucket wheels

· Transfer conveyors

MOW equipment Components:

· Tie crane boom

· Lift table

· Tie extractor

· Ballast regulator wings & center sections

· Spiker axles

· Tie crane axles

· Cylinders

Brands We Make Even Better

Technical Data Sheets

Case Studies

Proven Solutions From Our Trusted Partners

We are proud to build partner relationships that expand our value through distributing quality solutions from trusted brands in operations across heavy industry. These partners share our commitment to the highest quality and safety standards, responsive service, and constant drive for innovation.

Have A Big

Challenge?

We’re ready for anything.

No problem is too big or too small. Our expert engineers, manufacturers, and field service technicians love a good challenge and routinely solve complex issues for operations globally.