Draglines

Keep Digging

When production is down with unexpected maintenance, and your mining dragline needs replacements, repairs, or a complete overhaul, count on L&H Industrial. Our seasoned team of specialists designs, engineers, manufactures, monitors, and maintains dragline components, applying the critical insight and experience our field experts gain through servicing draglines across the globe.

Improving Operations

When a machine goes down, we’re the dragline maintenance, repair, and rebuild partner your operation needs to get you back online fast and running better than before. We transform dragline systems to improve lifecycle performance and safety, while significantly reducing operating costs. Our proprietary metallurgy, custom engineering, and precision manufacturing extend component, assembly, and machine life all backed by our 24/7 responsive field services for support in the field whenever you need it.

Rebuilding Better

Our experienced engineers, mechanics, welders, and machinists are ready to upgrade your mining dragline components and assemblies. We can rebuild and vastly improve performance and safety for entire dragline systems, structures, and attachments including walking arms, cams, gearboxes, buckets, lattice booms, tubs, and house. Need a custom solution? We’ll design, build, and install it on-site so you can get back to business.

L&H Innovations

With our specialized design, engineering, manufacturing, and monitoring capabilities and a nimble and practical partnership approach, our industry-leading solutions vastly improve mining dragline operating efficiencies.

Direct Replacements

We apply our extensive industry experience to a comprehensive offering of replacement parts, from rails and rollers to pins, shafts, and structures. Our superior replacement components reduce downtime and help you reach your business goals.

Custom Solutions

Your biggest challenge is our team’s specialty. We’re ready to handle unique use cases and create custom solutions for draglines by designing the highest quality components—from gearing to transmissions, fixtures, and structures.

Simply

unmatched

Components

100% of L&H premium components meet, or more often exceed, OEM performance, quality, and safety standards.

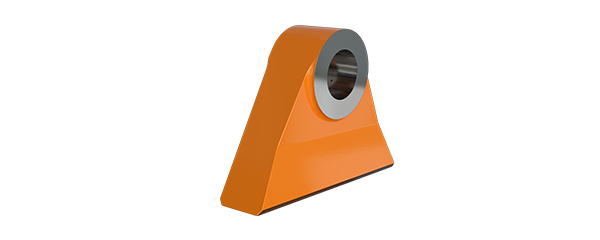

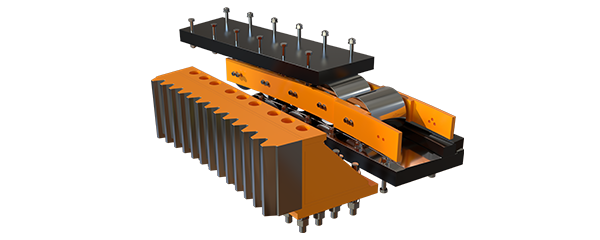

Shoe Inserts

Our upgraded components increase strength with full-length lugs and a heavier top plate.

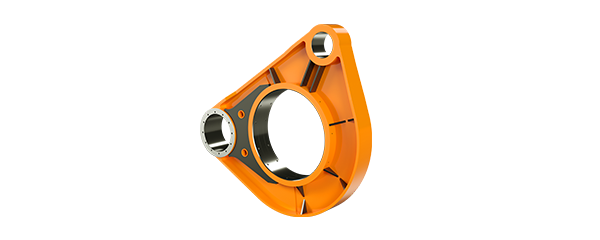

Universal Walking Arm

Our unique, stronger-than-cast, L&H-forged crank addresses OEM design pitfalls, can extend the walking arm lifespan by up to 50%, and eliminates the need to buy a left or right arm.

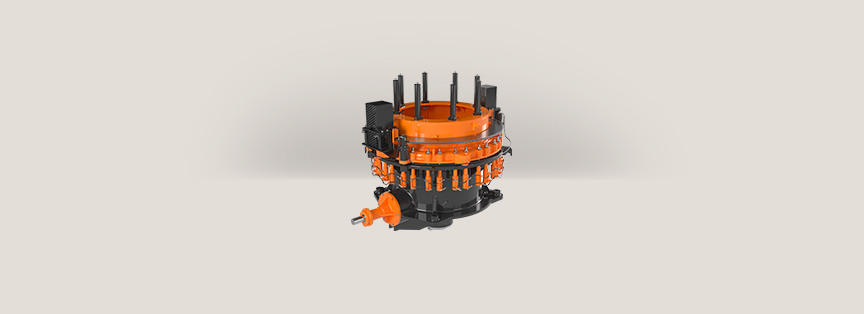

Swing System

L&H self-aligning rollers are the first-ever carrier systems that move and flex with your draglines, eliminating derailments and dramatically reducing maintenance.

Ready for increased productivity and a partner in maintenance?

Components & Assemblies We Enhance

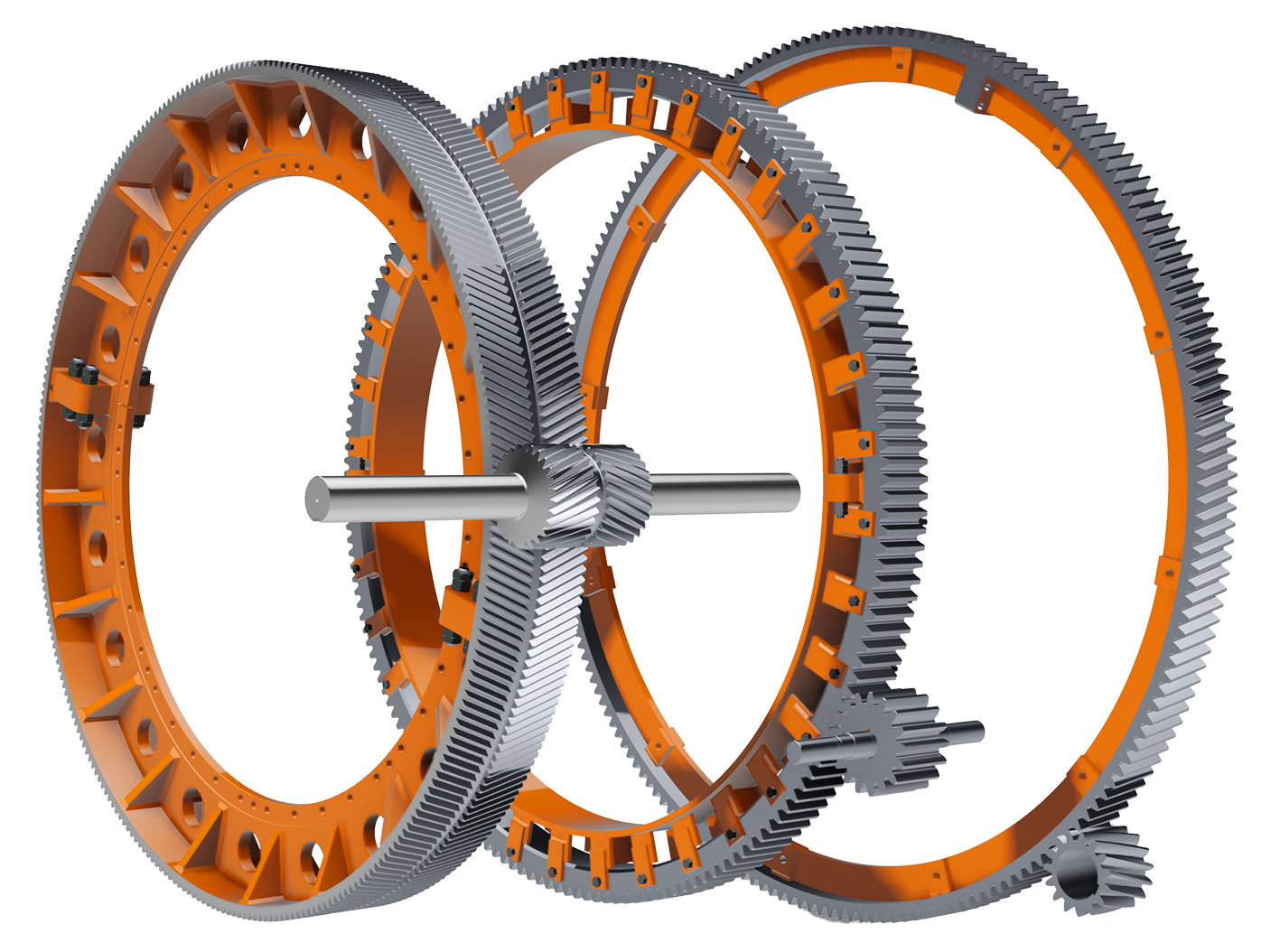

HOIST & Drag SYSTEM

· Transmission

· Drums

· Drum shafts

· Gearing and shafting

Swing system

· Racks

· Rails

· Rollers

· Center pins

· Pinions

· Shafts

· Swing transmission

Propel system

· Tubs

· Walking shoes

· Walking arms

· Stabilizer links

· Gearing and shafting

· Gear hubs

· Walking eccentrics

Attachments & structure

· Buckets

· Buffer cylinders

· Gantry lug upgrades

· Booms

· Boom foot upgrades

· Back legs

Brands We Make Even Better

Field Services We Offer

· Machine rebuilds

· Rush breakdown repairs

· On-site machining

· Component installs

· UT analysis

· Failure analysis & troubleshooting

· Full machine audits & inspections

· Equipment relocations

· Machine customizations

· Teardown, relocation, and commissioning

Have A Big

Challenge?

We’re ready for anything.

No problem is too big or too small. Our expert engineers, manufacturers, and field service technicians love a good challenge and routinely solve complex issues for operations globally.