L&H’s Newest Advanced Horizontal Lathe

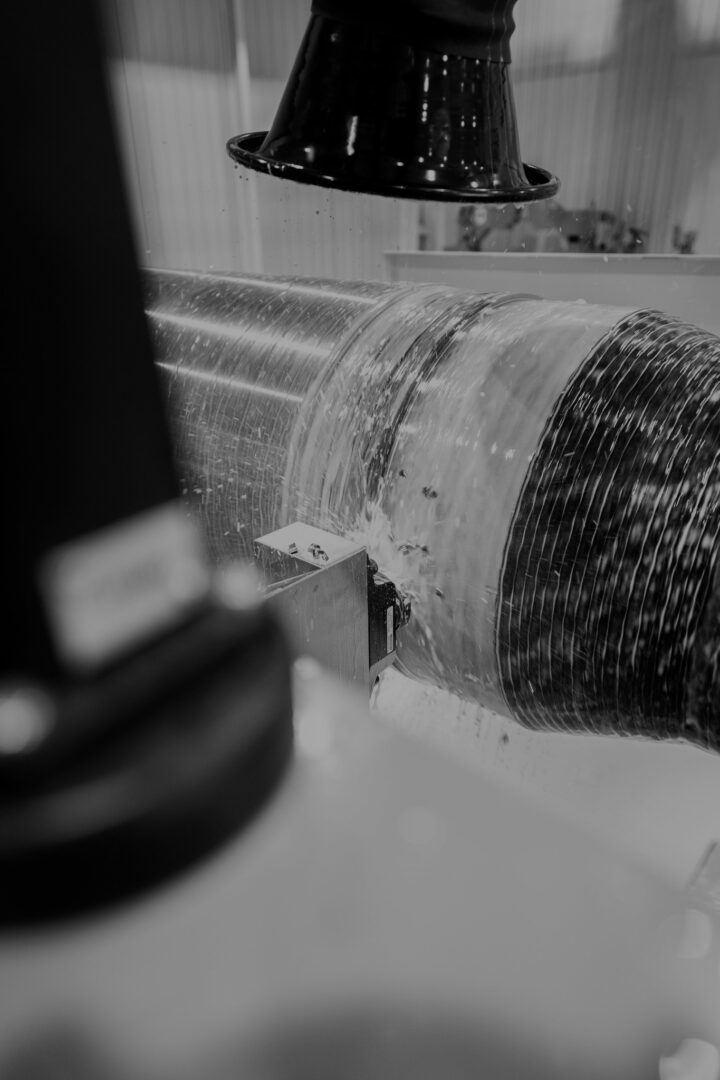

At L&H Industrial, we’re constantly pushing the limits of what’s possible in heavy machining. Our latest investment—a state-of-the-art horizontal lathe—is a game-changer for industries that demand precision, power, and efficiency. Designed to handle the most massive and complex components, this machine is set to transform the way we serve customers across mining, power generation, space and beyond.

Built for the biggest jobs

When it comes to machining large-scale components, size matters. Our new horizontal lathe offers unparalleled capacity, allowing us to turn, cut, and finish some of the heaviest and longest parts in the industry. This impressive machine’s specifications include:

– Turning Length: Up to 10,000 mm (32’)

– Swing Diameter: 3,000 mm (118.1″)

– Max Workpiece Weight: 40 tons (without steady rests), up to 80 tons (with steady rests)

– Live Tooling & Y-Axis Capability: Enables precision milling, drilling, and tapping in a single setup

With these advanced features, we can now machine everything from mineral processing shafts to wind turbine main shafts, hydro shafts, and other large-scale industrial parts.

Precision & Efficiency in Every Cut

But it’s not just about size. It’s about capability. This horizontal lathe enhances our accuracy, reducing cycle times and improving surface finishes—critical factors that make a big difference in the ability to produce higher-quality components faster—keeping our customers’ operations moving without unnecessary delays. Additionally, the integration of live tooling and the Y-axis further expands our machining versatility, allowing us to handle intricate tasks for the most complex components.

Building Trust: A One-Stop-Shop for Heavy Industry

What does this mean for our customers? Simply put: more options, faster turnaround times, and improved consistency. With the new lathe, we can do everything under one roof—from turning the big pieces to milling, drilling, and tapping, all with the same machine. This consolidation not only saves time but also cuts down on costs, offering a truly competitive advantage in the marketplace.

Experience the Difference

This investment builds on our core value of being a one-stop shop. When our customers need a turnkey solution, L&H has the capacity to meet the toughest heavy-duty machining requirements.

With the addition of this powerful horizontal lathe, L&H Industrial is now positioned to handle larger, more complex parts for industries that continue to require larger and more precise components to power the world’s largest machines. This massive lathe marks a new chapter for our manufacturing operations and helps us stay at the forefront of industry advancements.

Additionally, this new investment is more than just a machine—it’s a commitment to our customers. L&H Industrial has spent 60 years engineering, repairing, and manufacturing the most critical components for the worlds hardest working industries. This lathe reinforces our ability to support customers throughout their machine lifecycle, from engineering and design to precision machining, repairs, and field services.

By combining state-of-the-art equipment with our team’s expertise, we are setting new standards for quality and efficiency in heavy-duty machining. Whether it’s large parts, intricate designs, or strict tolerances, L&H has the equipment, experience, and commitment to deliver on any challenge.

Ready to Learn More?

If you’re looking for a machining partner who can handle your largest, most complex parts, L&H Industrial is here to help. Download the full machine slick and get detailed specs on the new horizontal lathe. Discover how this powerful machine can help take your operations to the next level.