swing systems

in full swing

mining doesn’t stop

and neither do we

When your machines are in motion, your operation depends on steady, reliable performance. L&H Industrial builds swing system solutions that keep your electric rope shovel fleet running longer and with fewer failures. We don’t just replace worn components. We engineer better solutions that extend service life and reduce long-term maintenance costs.

With proven design, tight-tolerance manufacturing, and field-tested performance, our swing systems help your team stay focused on production, not repairs.

this isn’t just about replacing parts

It’s about upgrading performance.

CATERPILLAR/BUCYRUS SYSTEMS

• Swing Pedestals – Designed for extreme-duty mining and available new or through L&H’s industry-first exchange program

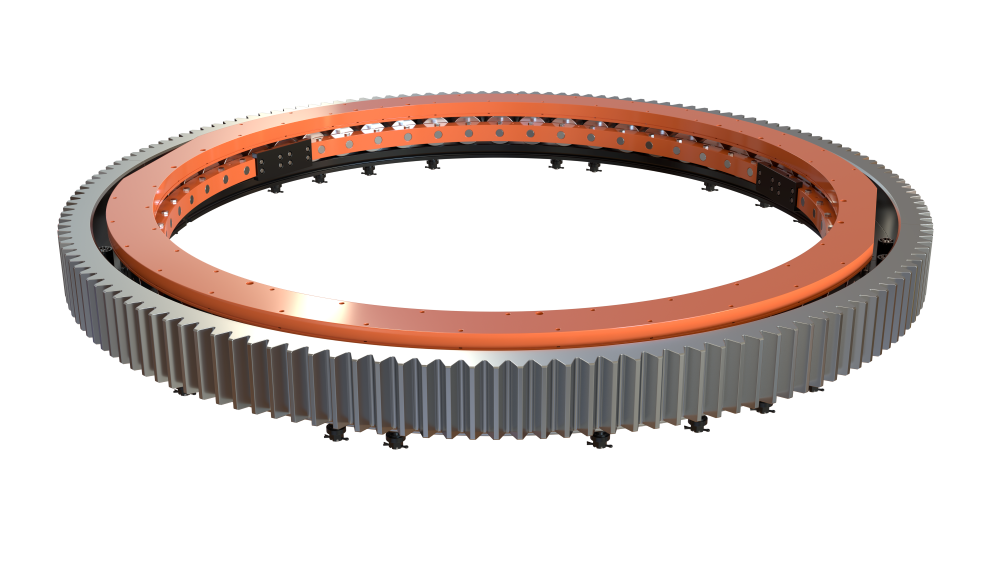

• Bolt-On or Integral Swing Gears – Engineered from seamless rolled ring forgings, available in single-piece or two-piece designs for simplified maintenance

• Upgraded Roller Assemblies – Featuring a cageless design that eliminates frequent adjustments and reduces hardware failures

• and more…

KOMATSU/P&h SYSTEMS

• 3rd Rail Thrust System Upgrade – Makes the thrust surface replaceable to extend overall system service life and also improves roller containment and increases thrust surface area to reduce wear rates

• Extended-Height Rail Segments – Increase revolving frame stiffness by over 45% to improve roller load sharing, enhance performance, and reduce the need for structural repairs

• Field-Optimized Swing Gear Fitment – Ensures precise gear alignment, reducing vibration and premature wear

• and more…

design & engineering:

When standard designs fall short, L&H Industrial engineers a better way forward. Through thoughtful and targeted enhancements, we improve reliability and reduce long-term operating costs. From roller carrier assemblies redesigned to eliminate the cage and simplify installation, to rail profiles optimized to reduce stress concentrations and wear, our upgrades deliver lasting performance and lower total cost of ownership for your shovel fleet.

manufacturing & repair:

Precision manufacturing at scale requires world-class equipment and expert tradesmen who know how to get the most out of every machine. At L&H, our teams operate some of the largest and most capable manufacturing equipment in the industry, delivering tight tolerances on critical swing system components. Our facilities are built for throughput and accuracy, allowing us to produce, rebuild, and enhance key shovel components with quality that meets or exceeds OEM standards.

MONITORING & CONTROLS:

Instrumenting your swing system is one of the best ways to gain insight into real-time performance. At L&H, we can integrate monitoring tools to track parameters like temperature, vibration, and load conditions, making it possible to identify early signs of wear and stress. These insights support predictive maintenance and more to protect your most critical shovel components. Whether you are starting small or building toward a fully instrumented system, we can help.

FIELD SERVICES:

Keeping your swing system running takes more than quality parts, it takes expert technicians who know how to inspect, align, and maintain critical assemblies in the field. From routine inspections to full system planned overhauls or unexpected repairs, we work closely with your crew to keep shovels operating reliably and safely. With portable machining, specialized tooling, and proven repair procedures, we help reduce downtime and extend the life of your equipment.

real results. real performance.

You don’t have to take our word for it.

see for yourself how we challenged industry norms when the pressure was on.

The problem

A critical shovel rebuild with a firm 28-day window was complicated by unexpected crawler frame damage and over 130 feet of structural cracking, putting both timeline and production at risk.

The solution

L&H executed a full swing system replacement and structural repairs through integrated design, in-house manufacturing, and fast-reacting field services—all without extending the original timeline.

THE RESULTS

L&H completed the full swing system replacement—plus 130 feet of structural repair—within 28 days. No timeline extensions. No safety incidents. The shovel returned to service weeks faster than industry norms, minimizing downtime and restoring production with precision and speed.

let’s build something that lasts.

It’s time for an upgrade.

Don’t wait for failure. Maximize uptime, reduce risk, and extend the life of your shovel.

Request your swing system quote now and keep your fleet IN FULL SWING.