L&H Industrial has repaired, rebuilt and manufactured mining parts for over 50 years. Understanding how parts break and what makes them fail is what we know best, and improving them is our specialty.

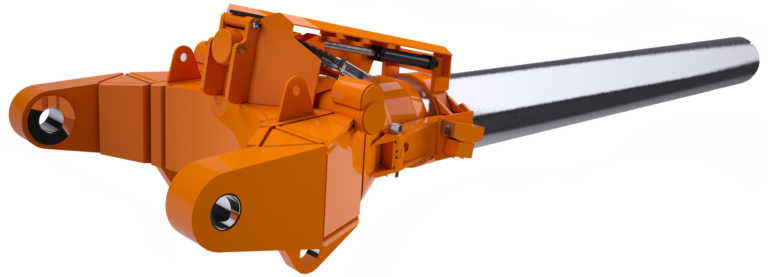

The 495 handle upgrades

The OEM handle design for 495 shovels is a recent example where L&H felt improvements could be made to the design to address the issues causing continuing failures. L&H engineers went to work on the new concepts to create a longer lasting, more reliable part for our customers.

After reviewing OEM design failures, three problem areas needed to be addressed: a cast yoke design, weak cross bracing, and high areas of fatigue. Each upgrade designed by engineering provides a solution for these areas.

SOLUTION 1:

Incorporating a forged yoke design created consistent hardness and composition as well as an increased bending strength of at least 30%. Additionally, the new design includes an increased transition and thickness, allowing for the ability to be rebuilt many times, where the OEM design had a rebuild life of only 3,000-5,000 hours.

SOLUTION 2:

By replacing the cross bracing with wrapper plates this allows for improved access for full pen welds and reduces cracking in weak areas due to the cast material.

SOLUTION 3:

By including a static retract yoke, transverse welds are minimized and further reduces fatigue. Furthermore, stronger retract arms were included, without ears on the forging and instead utilizing the pins and bushings.

With these combined design upgrades customers can now have access to a forged, repairable, re-buildable design with more pen welds. For rebuilds, customers can continue to use their old tubes and rebuild their handles while only needing a new yoke and transmission.

A long lasting re-buildable solution

L&H’s new handle design allows customers to mitigate safety hazards with less down time and allows for savings on maintenance costs. The re-buildable design lasts longer and requires less repairs. Another solution created in partnership with our customers to optimize their machine productivity, our new 495 handle is built to last.