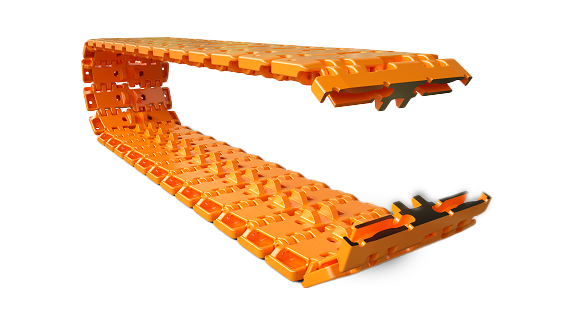

L&H Crawler Shoes for 49R Series Blasthole Drills: A Revolution in Undercarriage Performance and Durability

Mining operations never stop, and when it comes to your blasthole drill fleet, every component’s reliability and efficiency can make a crucial difference. Our Crawler Shoes for Bucyrus®/Caterpillar® 49R Series Blasthole Drills aren’t your typical crawler shoes; they’re the epitome of engineering excellence specifically designed to enhance your 49R series undercarriage performance. Some of the compelling features include robust manganese construction with stabilized pitch growth, ensuring long-lasting and predictable durability and exceptional wear resistance, and the drastic decrease in pin failures. The crawler shoe material has proven itself and increases the reliability of the undercarriage and increases life in the toughest mining conditions.