TRANSFORMING

THE BIGGEST

MACHINES

ON EARTH

Your

Partner

IN EVERY STEP OF THE PROCESS

Count on L&H Industrial for a full lifecycle partnership—from new designs for heavy machinery to legacy machine upgrades, and a global field service team that’s ready for your call 24/7.

Leave DOwntime

In the Dust

Design & Engineering

Optimize your operations with the expertise our team brings to developing one-of-a-kind innovations and advanced technology for heavy equipment across industries.

Manufacturing & Repair

Our world-class team of specialists manufactures and repairs components and assemblies using precision equipment in state-of-the-art facilities to improve operational safety and performance.

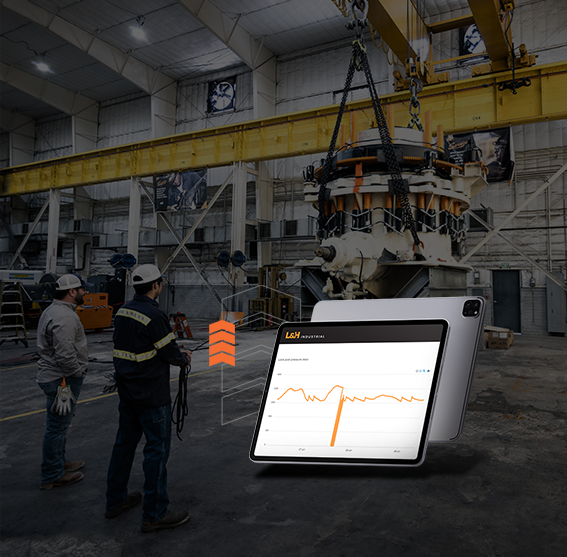

Monitoring & Controls

Our comprehensive digital solutions provide real-time insights for predictive maintenance and machine monitoring, ensuring you have the data you need, whenever you need it.

Field Services

Our experienced crew collaborates with and works alongside your team to troubleshoot, repair, rebuild, install, and even relocate your heavy equipment.

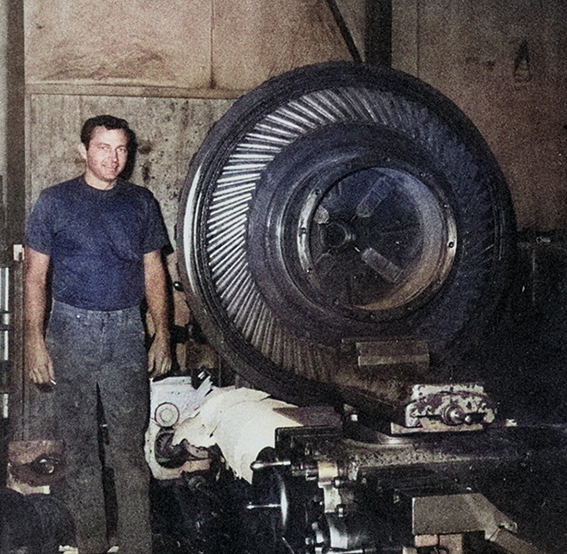

Quality & Trust for 60 Years & Counting

When you work with L&H you not only get components and assemblies that consistently exceed OEM performance, quality, and safety standards, but you also get a deep partnership built on a solid foundation of honesty and trust earned one machine at a time, with over 60 years in the field.

Where you

Need Us

When you need us

Maximize your uptime no matter where you operate. L&H has boots on the ground and partner locations that deliver responsive 24/7 service and repairs to heavy machinery customers worldwide. Don’t see your location listed? We’ll get you the team you need.

Better Solutions Derived From The Best Talent

We know from experience that it takes the most talented people on Earth to engineer, manufacture and repair critical equipment for the hardest working industrial industries. We’re confident in taking on machine challenges other companies think are impossible because we always hire the right people for the job. Our teams, like our machines, are built of the very best.

Have A Big

Challenge?

We’re ready for anything.

No problem is too big or too small. Our expert engineers, manufacturers, and field service technicians love a good challenge and routinely solve complex issues for operations globally.