Locations

GLOBAL Footprint

Local Relationships

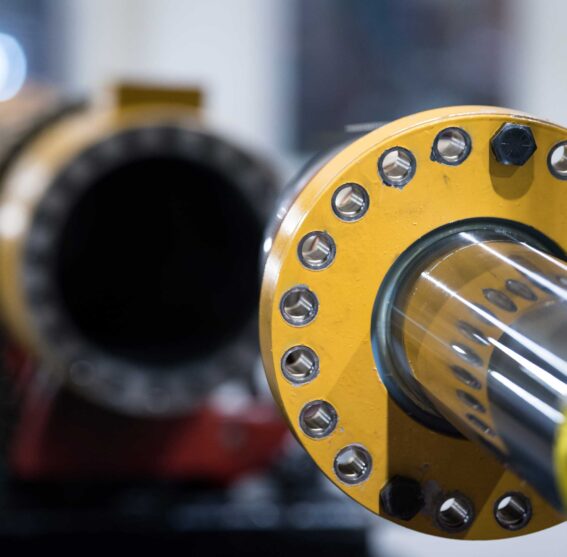

No matter where in the world you operate or what industry you serve, L&H is ready to help you solve your biggest machine challenges. Our shops feature state-of-the-art machines for fabrication, manufacturing, finishing, testing, and analysis that can handle large and complex parts with ease. We’re fully equipped and staffed to safely design, manufacture, rebuild, repair, and maintain the biggest machines on Earth as your full lifecycle partner.

USA

GILETTE, WYOMING

913 L&J Court

Gillette, WY 82718 USA

Tel: 307.682.7238

Fax: 307.686.1646

USA

SHERIDAN, WYOMING

1909 Commercial Ave

Sheridan, WY 82801 USA

Tel: 307.674.4431

Fax: 307.674.4510

USA

TEMPE, ARIZONA

1710 W. Broadway Road

Tempe, AZ 85282 USA

Tel: 480.968.6141

USA

HERMOSA, SOUTH DAKOTA

14305 Broken Spoke Place, P.O. Box 437

Hermosa, SD 57744 USA

Tel: 605.255.5970

Fax: 605.255.5980

canada

EDMONTON, ALBERTA

L&H Canada

600, 12220 Stony Plain Rd

Edmonton, AB, CANADA T5N 3Y4

Tel: 307.680.9940

Fax: 307.686.1646

MEXICO

CANANEA, SONORA

L&H Mexico

Ave. Juarez #36

Cananea, Sonora 84620 MEXICO

Tel: 011.52.645.332.6161

Fax: 011.52.645.332.5083

MEXICO

SALTILLO, COAHUILA

L&H Mexico

Perif. Luis Echeverria #1205

Col. Guanajuato Ote.

Saltillo, Coahuila 25280 Mexico

Tel: 011.52.844.350.5417

CHILE

LA NEGRA, ANTOFAGASTA

L&H Chile

Hector Gomez Cobo 02405

Sector La Negra

Antofagasta, Chile

Tel: 011.56.552.560156

A Few Shops

In action

Gillette, WY

Sheridan, WY

Tempe, AZ

Our Partners

And distributors

L&H is proud to work with these valued partners and distributors whose commitment to quality, safety, and innovation helps us bring added value to our global customers.

USA

Like L&H, LCM believes in optimizing equipment performance to increase incremental equipment reliability that your company needs to achieve a lower total cost of ownership.

Brazil

Grupo Hidrau Torque is a leading distributor of parts for heavy equipment with a strong presence throughout Brazil.

Australia

Mainetec is an Australian company that provides superior-quality products and services to its customers.

Have A Big

Challenge?

We’re ready for anything.

No problem is too big or too small. Our expert engineers, manufacturers, and field service technicians love a good challenge and routinely solve complex issues for operations globally.