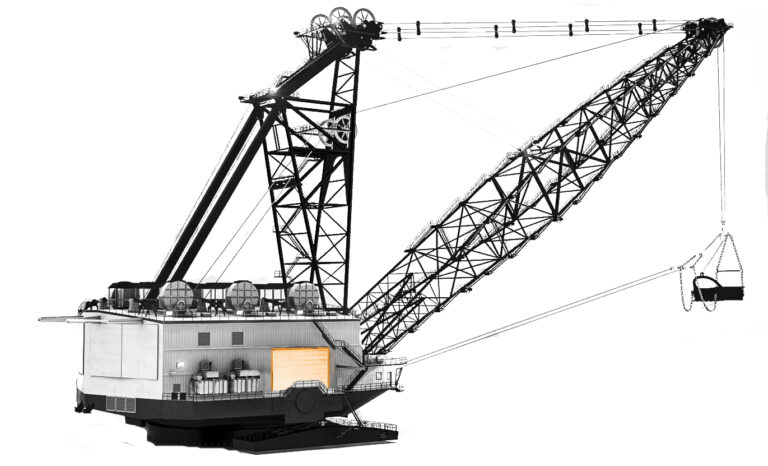

Removing and installing large components from mining machinery takes time and can create safety hazards. Draglines, specifically, are full of massive transmissions, drums, gearing and other components that have to be removed from the machine for rebuilds or replacements. Removing these components is typically done by opening large, heavy, mechanical doors on the machine that are often not reliable.

While servicing draglines, L&H realized there should be a safer and more efficient way to remove and replace components from these machines. After installing Megadoors throughout wash bays, truck shops and mine entrance doors over the years, L&H believed the concept could be incorporated onto large machines as well, and did so for a customer in the Powder River basin. The mine received the first high speed, translucent fabric door on a dragline that will create safer and more efficient future maintenance practices.

The Megadoor

The grit and grime of often corrosive environments combined with weather and temperature conditions can create undesired working conditions during machine maintenance. To address this, is a highly reliable door made of translucent fabric with corrosion resistant components was installed for easy and secure operations. The translucent fabric increases light in work areas and can withstand high winds by evenly distributing the load. Its innovative design creates flawless functionality providing secure access to the gigantic shops and machines on mine sites.

Improved safety and efficiency

Requiring minimal maintenance and maximizing safety, the Megadoor requires less space with a compact design and generates low weight on a building or machine structure. Also providing a tight seal when closed, a comfortable work environment is created while saving energy. Without springs or counterweights and very few moving parts, the door ensures long term reliability and very little maintenance.

Travis Ziegler, L&H’s lead field technician on the project, explains the added value the new Megadoor would bring to the customer. “The new 28×15 foot door really opened up the machine creating a lot of added light. Additionally, the new door created an extra 5-6 feet of head room allowing for mobile cranes to easily access swing cases and other components for tear down.”

Incorporating the Megadoor onto our customer’s machine offers a number of benefits for maintenance creating safer and more efficient operations. To learn more about installing a Megadoor onto your machine, contact L&H Industrial today.